Project Results

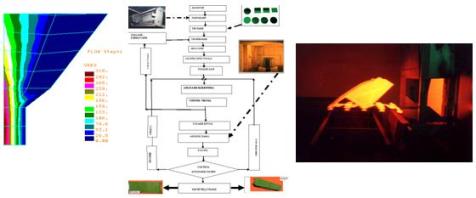

The project has proposed and has created a new material (developed by the Romanian specialists) resistant to high temperatures, wear and corrosion, integrated with an original technology, intended to cover the surface of the elastic components of the turbo motors.

The objectives were achieved, the prototype was developed (a fitting turbo motor R13 - F 300 (95) with components whose surface was covered with new material created using the original technologies created in the project.

The surface coatings’ use, in the project’s case the thermo resistant emails, have logic in their property to form on metal layers, hard, refractory and impervious surfaces against the substances from waste gases with good mechanical properties (resistance to shock, rupture, elasticity, etc. .) at high temperatures and high resistance to thermal shock, coupled in the project case, with the wear resistance, abrasion and corrosion. By thermo resistant enamellings, the parts or the components of the turbo motors increase its length of life, as ordered by doubling the size.

The essential desired properties are: refractory, resistance to high temperatures, compatibility with the material (adhesion, coefficient of linear expansion) resistance to thermal shock, coupled with resistance to corrosion and wear. It should be noted here that the research addresses to the elastic components of the turbo motors, so very complex regions. The problems proposed for solving were extremely complex, emphasizing the multidisciplinary character of the research; activities in physics, of chemistry, of mathematics, mechanics, metallurgy and not the least of the aircraft. The complexity quite special, the special character tilt towards fundamental research in various fields, linking them to obtain an integrated, efficient system, with immediate practical application, has a research character placed to the scientific frontier and technical knowledge.

Developing a new and outperform material, developing of special technologies, all being finished with a coat of mail, with special features which allows it to be used on the elastic component of turbo motors is an absolute novelty for our country but also for firms with industry leading aeronautics.

The project was generated by the aeronautical industry requirements, be represented in this case by AEROSTAR Bacau, who actively participate in this project. Surveys were conducted starting from the parameters of operation and technical features related to the adverse situations that may occur in power use, the beneficiaries permanently monitoring the obtained results (in many cases actively participate in obtaining them).

The performances obtained in the testing results are remarkable, the tests and attempts made being edifying and recognized by all stakeholders.

This situation has generated a strong response from the principal beneficiary AEROSTAR Bacau, which started and to which there has been technology transfer activities and the implementation of the results. In the final stage (when the results are certain), the recipient could develop, together with the directly involved researchers, detailed technical-economic analysis, which has clearly showed the international competitiveness of the proposed solutions (already applied for the Egyptian Air Force at a base of Cairo), of the obtained results, this standing to the base of the insurance decision for the all materials necessary in the technology transfer.

The main beneficiary of the project, AEROSTAR Bacau, has extensive national and international markets for selling its products; the project results will be perfectly integrated in this market which is generated from them needs, attributing to Romanian products some particular characteristic, reason which will clearly increase the competitiveness of the products.

We must mention here that the application of the research carried out increased the degree of trust of the foreign beneficiaries in the Romanian aeronautical industry products, which not only led to increasing the demands but to the training of Romanian producers and researchers from turbo motors domain in solving those problems (ex. premature destruction of compressor‘s palettes that works in special climate zone).

The impact of technical - economic results is certainly tests up to this time showing clearly that he materialized in:

- Increasing the duration of operation (about twice)

- Reducing the cost price (to approx. 15%)

Project Events

The project is presented on a Web page http://materiale.comoti.ro, COMOTI Bucharest; it was presented through scientific communications that took a real interest in CEEX conferences.

The project results have already been promoted, primarily through works: INCREASING GAS RESOURCE Turbine by combining COOLING FILM AND CERAMIC COATING -2 and international Conference on thermal and Environmental Engineering-2007-Galati; “Possibilities to increase the turbo motor’s resource in the cogenerated cycle by the pelicular cooling and by the thermo resistant coverings”, modern science and energy Edition XXIII, Technical University of Cluj-Napoca, ISBN 973-656-440 -1, pag.117.

Is not negligible the promotion done by AEROSTAR Bacau at the international level, among its beneficiaries which stabilized confidence in the Romanian products and scientific research capacity of our country to solve problems of particular importance to aeronautical industry.

|