Stage 1

1.1. The Study realized by the members of the consortium in the frame of the first stage comprises:

- noise legislation;

- theoretical analyzing regarding the possible noise sources from the natural gas compression stations;

- description of the established location;

- innovative methods use worldwide to reduce noise in the natural gas compression stations;

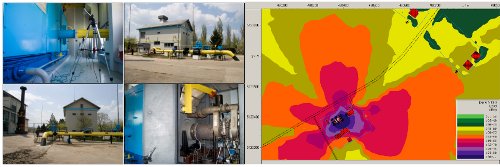

- acoustic and vibration measurements performed at the established location.

1.2 Active participation at the actions organized by the Joint Research Centre in the field of noise mapping (Workshop on Noise mapping according to the 2002/49/EC: "TARGET QUALITY AND INPUT VALUES REQUIREMENTS", co-organised by The European Commission (DG JRC, DG ENV and the European Environment Agency). More details regarding this event you can find accessing the following link: http://ihcp.jrc.ec.europa.eu/events/Past_Events_Mar_Apr_09.htm

1.3. Publishing the article “Aircraft Noise Modeling and Noise Perception through CDA Procedure, the Impact on Communities”, authors Adina Ionescu – COMOTI and Horia Dumitrescu – UPB. The AIAA/CEAS Aeroacoustics Conference took placed during 11 - 13 May 2009, Florida, USA. The paper has the registration number: AIAA-2009-3399. Due to the economical situation at this event we chose not to participate, only to publish the article.

1.4 Participated at trainings organized by the RENAR (Romanian Accreditation Association) / SR EN ISO/CEI 17025: 2005 Requirements presentation (with final testing)

Stage 2

2.1. The Study realized by the members of the consortium in the frame of the second stage comprises:

- Experimental Research at different locations and creating a data bases with the measurements results obtained;

- Establishing the solutions which will be implemented in order to reduce the noise of the natural gas compression station with centrifugal compressors;

- Establishing the solution which will be implemented to reduce the noise from the regulation and measurement stations;

- Conclusions regarding at the studies performed during Stage 1 and 2 and establishing the objectives to be accomplished during stage 3 (2010).

2.2. Acoustic measurements performed in the INCDTurbomotoare – COMOTI high speed blade machines experimental test bench (MPIT)

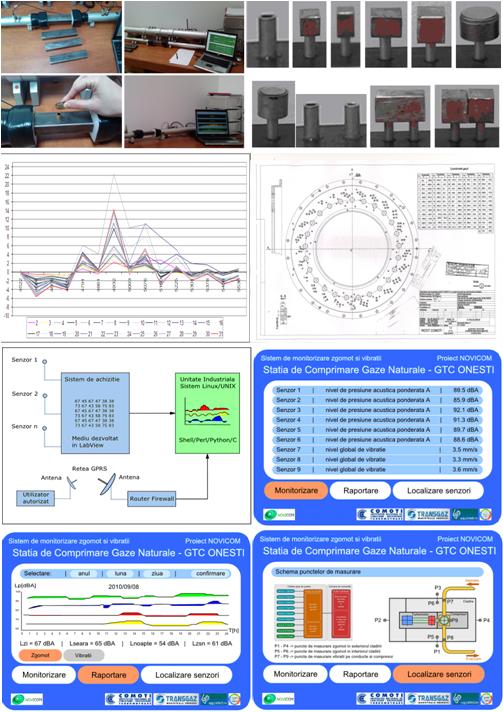

In order to obtain reliable and high quality results the consortium has been chosen to experiment the new solution o reduce noise at centrifugal compressors on a functional model in the MPIT test bench in the frame of the COMOTI Institute. In order to compare the results which will be obtain during next stage we performed acoustic and vibration measurements at the existent system.

The centrifugal compressor from the test bench was realized during the Research Project nr. 753 / 2006 – CEEX 2006 Program, entitled: „High efficiency equipment used for underground gas storage in areas that face difficulties in supplying gas”.

2.3 ISI Publishing the article entitled “Acoustic Measurements and Scenarios to reduce noise at a natural gas compression station”, in the Proceedings of International Conference DAAAM, Vienna, ISSN 1726-9679, authors: Adina Ionescu- COMOTI, Silviu Ionescu – COMOTI, Radu Codoban – COMOTI, Magheti Ioan – UPB, Enescu Nicolae – UPB

2.4. Prezenting and publishing the article “Noise monitoring at the natural gas compression stations. Environmental impact” in the frame of the SISOM Conference 2009, authors: Adina Ionescu – COMOTI, Silviu Ionescu – COMOTI.

Stage 3

3.1. The study carried out in the frame of the third stage is presenting:

- The theoretical research regarding the noise reduction estimation using different types of resonators which are acting at the EEISG-COMOTI centrifugal compressor central frequency established in the second stage of the project ( elaborating the noise reduction solution documentation );

- Resonators experimental models execution and laboratory testing the solution theoretically studied;

- Optimum resonator selection and implementing them in the EEISG-COMOTI centrifugal compressor geometry ( Designing the EEISG-COMOTI centrifugal compressor noise reduction solution );

- Monitoring system establishment (technical specification) and cost estimation;

- Monitoring points locations establishment, logical scheme, monitoring software development;

- Conclusions and establishing the objectives for the final stage (year 2011).

3.2. Acceptance the article entitled: „ Experimental approaches to reduce noise at source for a centrifugal compressor” for publication in the UPB Scientific Journal.

3.3. NOVICOM Project public evaluation accordingly with UEFISCDI requirements (download *.pdf presentation)

|